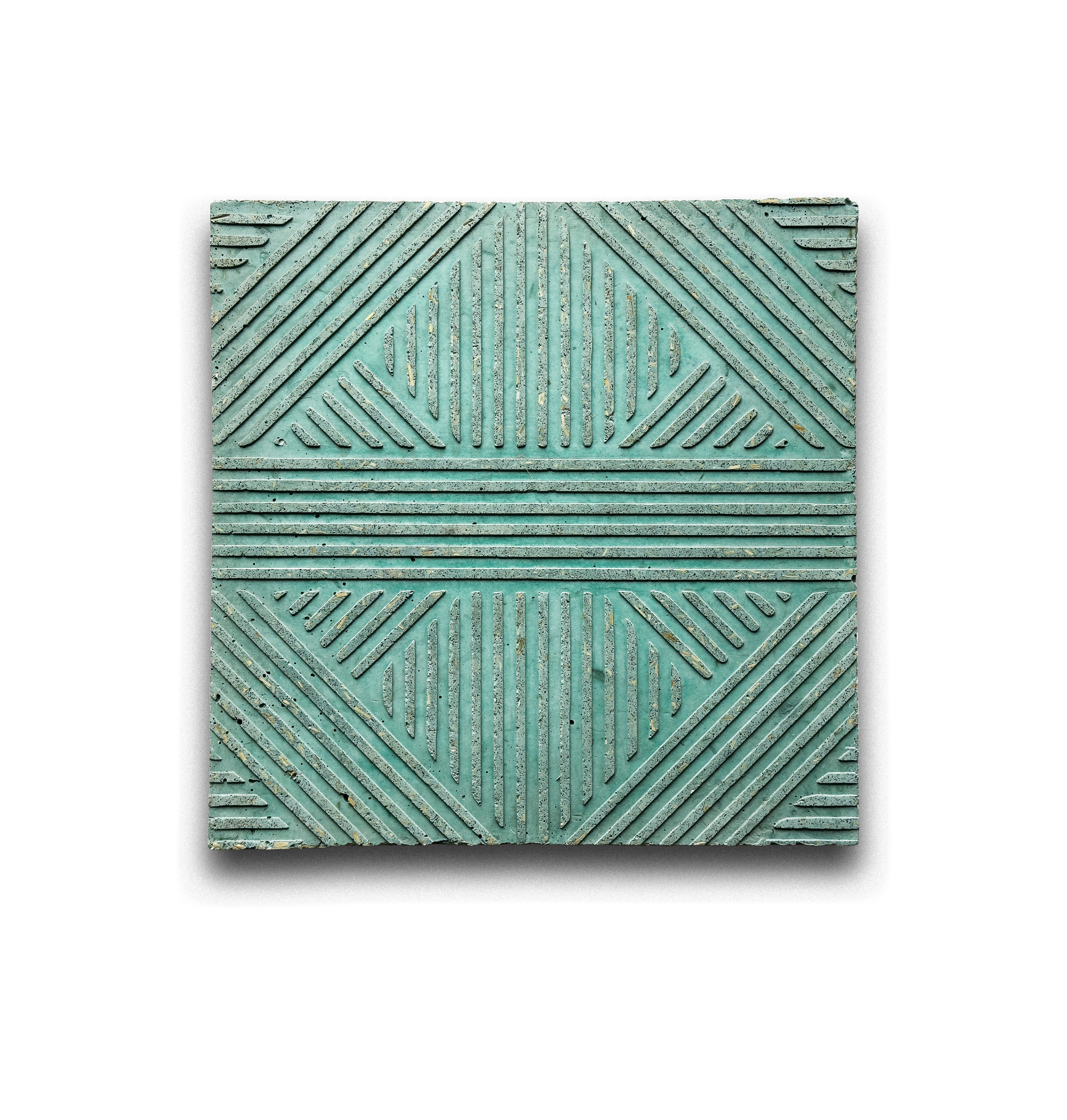

Cast Carbon is a wall tile that imparts earthy elegance to any space. Made from plant- and mineral-based ingredients, it not only beautifies interiors but can ultimately be returned to nature as a nutrient-rich, restorative soil conditioner.

beautiful AND ethical

biodegradable YET durable

fireproof WITHOUT flame retardants

carbon negative by nature NOT offsets

enhancE your LEED points with EASE

Cast Carbon is beautification, nature regeneration and soil restoration in a square. We’re your Cradle-to-Compost specification.

Designers, we’re here to help you create spaces that are good for your client and the earth.

Since people spend 90% of their lives indoors, they now expect spaces that support beauty, performance, health and ethics—especially through a deeper connection to nature. With proven benefits like healing, stress relief, and talent retention, biophilic design is no longer a trend but the standard. Designers shouldn’t have to be toxicologists to meet it—let’s make it easy to create clean, beautiful interiors where people and nature thrive.

-

Provide your clients a differentiated, high-nature experience that everyone can feel good about.

-

Biogenic Carbon Storage + Carbon Negativity, Circularity, Material Health: all in one tile.

-

Let your walls tell your sustainability story and help you retain top talent through high-nature, resimercial finishes.

-

Leverage your next renovation cycle and nature to preserve asset value and compete with best-in-class buildings.

-

Help urban renewal also revitalize rural economies while meeting your strategic procurement, embodied carbon + zero waste goals.

Helping the Next Generation

A Little Bit About Us

Cast Carbon is created by PHYTOSTONE LLC, a woman-owned atelier focused on advanced natural materiality. Our team spans Western NY, Brooklyn, Virginia and Mexico.

Cast Carbon development is the result of grit and a love for the natural and human worlds we inhabit.